The Drool Eliminator by JDL

The Drool

Eliminator. Save money, down time, messy cleanups! For use with

Conventional Molding Processes, Structural foam or Gas Assist when

injecting "in article."

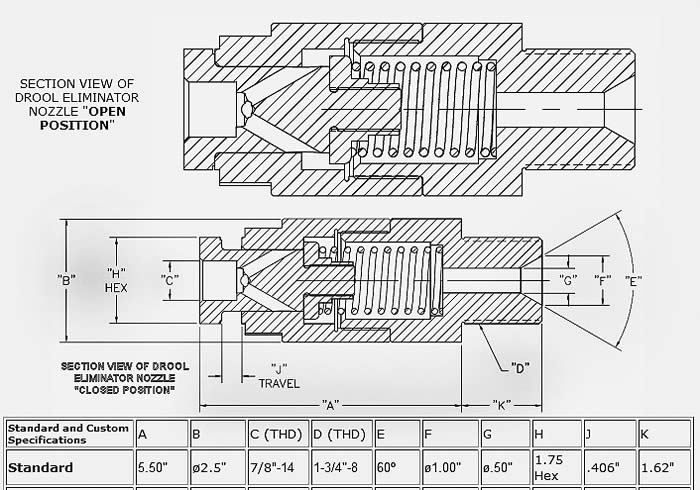

The Drool Eliminator uses a very heavy

spring-loaded mechanism to prevent nozzle drool. To operate, use the

sprue-break function on the molding machine to back off 1/2" from the

sprue bushing after resin injection and packing, and the nozzle is closed.

The Drool Eliminator comes with a special tool

for opening the valve for purging the barrel. After purging, remove the

special tool and you're ready for production.

In-process, the nozzle moves forward to the

sprue bushing, opening the valve for resin injection. After resin

injection and packing, "sprue break" approximately 1/2" and the nozzle

is closed.

Dimensions: 6" x 2.50", with 1 3/4"-8 male-end and 7/8-14 threads for standard nozzle tips. Available with non standard size molding machine end cap

threads for any molding machine.

Effective nozzle drool prevention for any hydraulic, electric, or hybrid injection molding machine.

|