Our task is to provide the best engineering support and most effective, efficient and repeatable gas assist molding accessories in the industry for optimization of your gas injection molding programs. We can offer recommendations for advancing your productivity and help you become a preferred supplier to your customers.

Your productivity is improved every day by Gas Assisted Injection Molding. We help make the products that bring you convenience and reliability.

Appliance handles · Medical equipment housings · Interior and exterior automotive moldings · Large covers and panels for office equipment · Lawn mower handles

Steering wheels · Structural moldings · Long tubular shapes, such as shovel handles · Large parts with ribs and bosses

Standard Gas Assist Injectors

Standard Gas Assist Injectors New AG4 Series

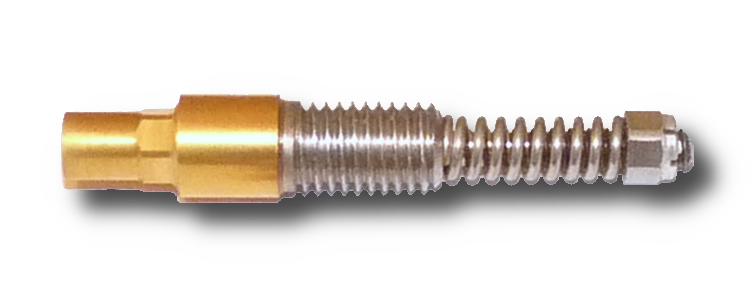

New AG4 Series High Pressure Gas Lines

High Pressure Gas Lines JDL Patented Check Valve

JDL Patented Check Valve Automatic Resin Shutoff Valve

Automatic Resin Shutoff Valve JDL Self Aligning Nozzle Tip

JDL Self Aligning Nozzle Tip JDL Rotary Resin Shutoff Valve

JDL Rotary Resin Shutoff Valve The JDL Drool Eliminator

The JDL Drool Eliminator Automatic Shutoff Valve/Nozzle

Automatic Shutoff Valve/NozzleGas assisted injection molding is the process. The right gas pins make gas assist molding efficient. Gaspins.com is an AEGIS site specializing in the selection and details for gas injectors, also commonly called "gas pins," plus the latest accessories for efficient gas assist molding. AEGIS also provides product, process, mold development and process optimization for any current or new gas assisted molding program. A key element to efficient gas assist processing is injector design for full pressure profiling capability. Gaspins.com is a selector and guide designed to provide essential information for selection of the right injector for your gas assist program, with basic installation details.

Gas assist injection molding programs differ in that product design, resin selection, gating and tool configuration affects the efficiency of your gas molding process. The gaspins.com guide is only that - a guide. Let us help with selection of the right injector, and how it can be best used in your new gas molding program. Our objective is to assure that your gas assist molding process runs with the widest, most trouble free manufacturing window possible.

AEGIS works with and provides services to only the industry's leading manufacturers of gas assist controls, gas compressors and nitrogen generators. We provide product analyses, product and tool conversion techniques, and hardware and accessories for efficient application of gas assist processes are our specialty.

Gas molding eliminates sink marks, reduces cycle times, greatly expands design options, reduces tool maintenance and secondary finishing time! AEGIS' staff can help you do the right thing the first time, with as short a learning curve as possible! AEGIS's team brings long term experience, adaptation expertise and processing efficiency to your operations. Let us help you reduce costs and become a preferred molder to your customers with gas assist molding methods.